Search

Address:CECEP Industrial Park, No.1336 Hangfu Road, Chongfu Town, Tongxiang,Jiaxing,Zhejiang,China

Tel:0086-571-86241135

Fax:0086-571-86241730

Email:info@wipexchina.com

Have you ever felt confused when making inquiries and communicating due to the inability to accurately determine the composition of non-woven fabric samples? Based on the decades of experience of WIPEX in serving global buyers, we are well aware of this pain point. Therefore, we have specially compiled this guide. Through several simple testing methods, it helps you make a quick and preliminary judgment on the material of the sample when you have it in hand, enabling you to have a more efficient and professional conversation with the supplier.

Introduction

As a buyer, knowing the basic composition of your spunlace nonwoven sample can significantly enhance the efficiency of communication with suppliers. Although laboratory test (like FTIR) is the only way to obtain precise results, you can use the following quick tests to form a reliable initial judgment.

Four-Step Identification Method

Step 1: Sensory Check (Look, Feel)

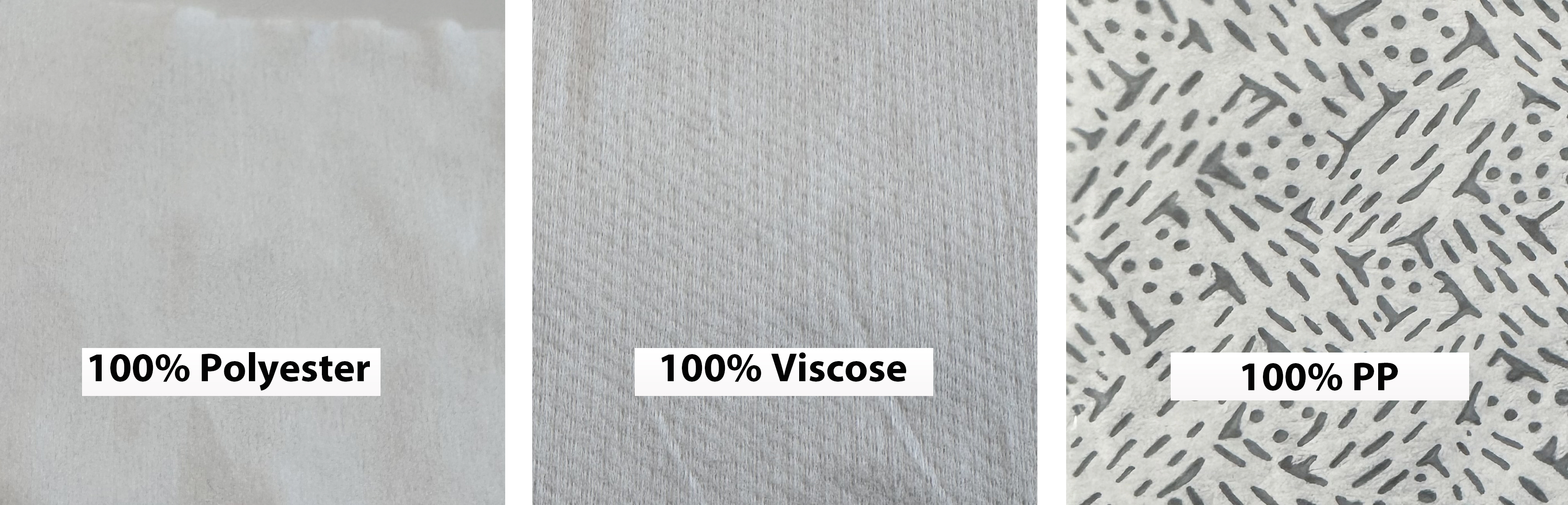

Appearance & Shine:

Polyester (PET): Usually has a pure white, shiny and bright fabric surface.

Viscose: Has a soft luster, presenting a matte or pearl-like luster, visually closer to natural materials.

Cotton: Has a pure matte texture, often in an off-white or creamy color. You might see small natural dark specks (cotton seeds) of the fabric surface.

Hand Feel:

Polyester: Smooth, sometimes with a slight slippery or plastic-like feel. This fabric is relatively stiff and will quickly return to its original shape when crumpled.

Viscose: The greatest advantage of this fabric is its super softness.

Cotton: Soft, but it also has a certain heaviness or fullness. It feels warm and has good water absorption.

Strength Test: Gently pull a fiber from the edge.

Polyester: Extremely high strength, hard to break, and can rebound after stretching;

Viscose: Strong when dry, but significantly weaker when wet.

Cotton: Fibers have a natural twist. It has strong strength in both dry and wet.

Step 2: The Burn Test

This is the classic and effective method for classifying fibers. Please conduct the experiment in a well-ventilated and safe area, using forceps to pick up a small amount of fibers for the test.

The core observation points lie in the burning state, flame color, burning smell, and the final shape of the ash.

|

Characteristic |

Polyester (PET) |

Viscose |

Cotton |

PP |

|

Near Flame |

Shrink and melt |

Does not melt and curls |

Does not melt and curls |

Shrink and melt |

|

In Flame |

Burns slowly with a yellow flame, and black smoke |

Burns quickly with a yellow flame |

Burns quickly with a yellow flame |

Burns slowly with a blue flame, and a yellow tip. |

|

Leave Flame |

Self-extinguish or continue to burn slowly |

Continue to burn rapidly |

Continue to burn rapidly |

Continue to burn |

|

Smell (Key Identifier) |

Sweet, chemical, or plastic odor |

Distinct smell of burning paper/wood |

Smell of burning paper or leaves |

Smell of paraffin or candle oil |

|

Residue/Ash |

Hard, black bead |

Fine, feathery gray/white ash that disperses easily |

Soft, grayish black ash |

Hard, yellowish-brown small balls |

Key Takeaway:

Distinguish polyester from cellulose fibers (such as cotton/viscose) : Smell is the key. Cellulose for the burnt paper smell and polyester for the aroma/plastic smell.

Distinguish cotton from viscose: viscose burns faster and more thoroughly, and the ashes are whiter and finer; The ashes of cotton are darker.

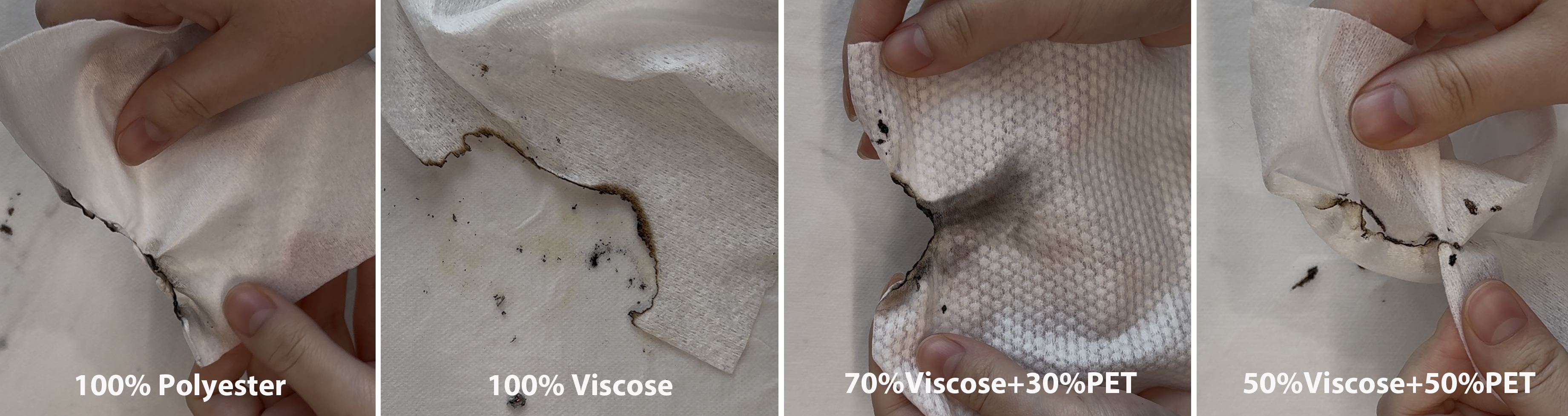

In addition, we can also roughly judge the proportion of viscose fiber and polyester fiber in spunlaced nonwoven fabrics by combustion method.

|

Characteristic |

100% Viscose |

100% Polyester(PET) |

70% Viscose+ 30%PET |

50% Viscose+ 50%PET |

|

Near Flame |

Does not melt and curls |

Shrink and melt |

Does not melt and curls |

Shrink and melt |

|

In Flame |

Burns quickly with a yellow flame |

Burns slowly with a yellow flame, and black smoke |

Burns quickly with a yellow flame, little black smoke |

Burns quickly with a yellow flame, and a black smoke |

|

Leave Flame |

Continue to burn rapidly |

Continue to burn slowly |

Continue to burn rapidly |

Continue to burn rapidly |

|

Residue/Ash |

Soft gray ash, burning without the hardness of plastic |

Hard, like black plastic residue |

Slight plastic hardness, some ash residue that can be broken by hand |

Black ashes, with small black plastic-like particles at the burning edges |

Step 3: Water & Dye Tests

Water Test:

Drop a drop of water on the fabric.

Cotton, Viscose: The drop will be absorbed instantly and spread fast.

Untreated Polyester: The drop will bead up and absorb very slowly.

Note: Many polyester fabrics are treated to be hydrophilic, so this test is suitable for untreated materials.

Simple Dye Test:

Using direct dye dissolved in hot water, dip a small cloth into the stain for several minutes.

Cellulose fibers (viscose and cotton): They will be stained quickly and obviously.

Polyester: almost no color at room temperature, or very light color.

This method can quickly distinguish between cellulose fibers and polyester.

Step 4: Make inferences based on the application

The intended use of a fabric is usually indicative of its composition:

1、For products with high water absorption and softness (such as disposable face towels, disposable bath towels, high-quality wet wipes, etc.) : They are very likely to be 100% viscose fiber or cotton. They provide top skin-friendliness and absorbency.

2、Regarding strength and durability (used for household, catering, industrial cleaning wipes) : They’re very likely to be polyester or polyester viscose blend. Polyester provides the necessary strength and stability.

3、Extremely thick and highly absorbent fabric: It is very likely to be a high-grammage 100%viscose or a high percentage viscose blend.

Summary:

When you have a sample, follow this order:

1、Infer possible components based on the application scenario

2、Perform the Burn Test: This is the important step to separate major fiber types. Focus on the smell. Use hand feel and ash residue to distinguish within the category (e.g., cotton vs. viscose).

3、Verify with Water/Dye: Use these as quick checks to confirm your burn test results.

If you need more specific and professional product in, please send us your samples immediately. We will provide you with a free professional assessment and offer you a one-stop solution that fully meets your requirements on disposable spunlace nonwoven fabric products.

FAQ:

Q1: If water droplets absorb quickly on the fabric, does that mean it's not polyester?

A1: Not necessarily. Only water test is not conclusive:

• If water beads up → Likely untreated polyester.

• If water absorbs quickly → Could be cellulose fibers (cotton/viscose) or hydrophilically treated polyester.

At this point, you need to do a combustion test (smell) to make the final determination.

Q2: How can I communicate with the supplier more professionally based on these initial judgments?

A2: You can inform the test results to the supplier of spunlace non-woven products. For example:

If the burning smell is of plastic, you can say: "The sample is suspected to be polyester." Could you recommend products with similar ingredients from your company or provide pictures? “

This will help you obtain more detailed and accurate product information from the suppliers.

Q3: How do I communicate with a supplier if I only have specific use case requirements and no clear product ingredients?

A3:You can inform the suppliers of the specific product application scenarios (such as in industries, hotels, restaurants, personal care, etc.) and the product features requirements (such as strong cleaning power, reusable, lint-free, etc.), and let them recommend suitable products for you.

Q4: What is the most important basis for judgment during the combustion test?

A4: The smell of burning is the most critical and reliable basis for judgment. Just remember two points:

If you smell a smell similar to burning paper, wood or ashes, the sample is likely to be made of cellulose fibers (including cotton, viscose, etc.).

If you smell a pungent chemical odor, a sweet smell, or a distinct burning plastic smell, the sample is likely to be made of synthetic fibers (such as polyester).

WIPEX wipers for the electronics industry are high strength, super clean, low-linting properties and...

WIPEX wipes work better than rags, are stronger and more durable than paper, and lower cost in use t...

WIPEX Aerospace Grade Wipes meet the toughest requirements from this industry. Our wipes are extreme...

Wipex Degreasing wipes are with excellent performance in using combination with degreasers. Made of ...

By high-tech German spunlace productionlines,our spunlace nonwovens are soft,no flufly,low linting,h...

Using hightech hydroentangling technology, WIPEX cleanroom wipers are lintfree,strong and uniform. O...

WIPEX has been in nonwoven market for 18 years. As a famous antibacterial wipes suppliers,Wiping Cloths Manufacturers and Nonwoven Wipes factory, We insist on cooperating with customer as a partner like a brother. We believe customers and workers are both our partners. We work sincerely with our brothers, we solve problem together with our brothers, we share success with our brothers!

WhatsApp:+8613588493391

WhatsApp:+8613588493391